Document Type : Research Paper

Authors

1

UKM, 43600, Bangi

2

Department Chemical and Process Engineering, Faculty Engineering and Built Environment, Universiti Kebangsaan Malaysia 43600 Bangi, Selangor

3

Departmen Chemical and Process Engineering, Faculty of Engineering & Built Environment, Universiti Kebangsaan Malaysia, 43600 Bangi, Malaysia.

Abstract

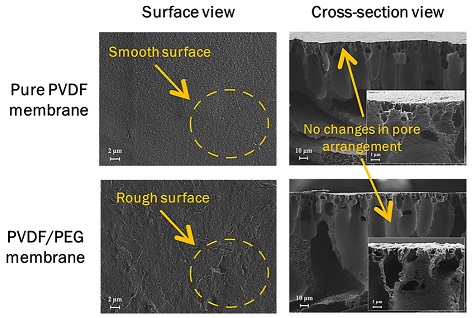

Palm oil mill effluent (POME) treatment through fermentation under controlled conditions generates biogas with an equal volume of biohydrogen (H2 ) and carbon dioxide (CO2 ). The H2 can be utilised for generating renewable energy through a hydrogen fuel cell. However, the existence of CO2 at certain concentration might cause cell poisoning. Therefore, gas upgrading is required. Membrane technology has been identified as one of the best methods for gas upgrading owing to its excellent purification performance. In this study, polyvinylidene difluoride (PVDF) membrane was synthesized at various polymer concentrations of 13-18 wt% through the phase inversion method before being coated with polyethylene glycol (PEG). From the results, the surface negativity and contact angle of the synthesised PVDF membranes were increased at higher PVDF concentration, therefore leading to increase in PVDF membrane’s hydrophobicity. As there was an increase in the membrane’s hydrophobicity, the membrane’s selectivity towards H2 increased as well, with the most H2 purity noted at 85%, which was attained by PVDF18 membrane. On adding PEG on the membrane surface, hydrophobicity rose from 81° (pure PVDF) to 100.8° (PVDF-co-PEG10). Moreover, PEG coating on the surface of PVDF membranes has enhanced their selectivity with the highest value of selectivity of up to 3.3. The PVDF-co-PEG10 membrane also has the highest H2 gas purity of up to 96% in comparison to pure PVDF membrane (only 85% H2 purity). This finding proved that PVDF-co-PEG10 membrane possessed a higher preference in the H2 /CO2 separation compared to pure PVDF membrane.

Graphical Abstract

Highlights

• PVDF membrane fabricated at different Cp to separate H2 fermented gases.

• Highest H2 permeability, selectivity and purity were obtained using Cp =18wt%.

• Surface modification of membrane further enhanced the selectivity.

• Modified PVDF/PEG membrane reached 96% H2 purity compared to control (85%).

Keywords

Main Subjects